- الصفحة الرئيسية

-

المنتجات

مشروع تسليم المفتاح

- معدات إنتاج ملاط البطاريات

- خط الإنتاج الكامل للسوائل السائلة

- خط الإنتاج الكامل للمواد اللاصقة

- خط إنتاج المسحوق الكامل

- تخزين السوائل ونظام الخلط الأوتوماتيكي

- تخزين المسحوق ونظام الخلط الأوتوماتيكي

- أعمال المقاولات العامة لمشاريع الهندسة والمشتريات والبناء والإنشاءات

- خط إنتاج الطلاء المائي

- خط إنتاج المعجون الكامل

- تكامل النظام

- الصناعات التطبيقية

- الأخبار

- الخدمات

- عن الشركة

- اتصل بنا

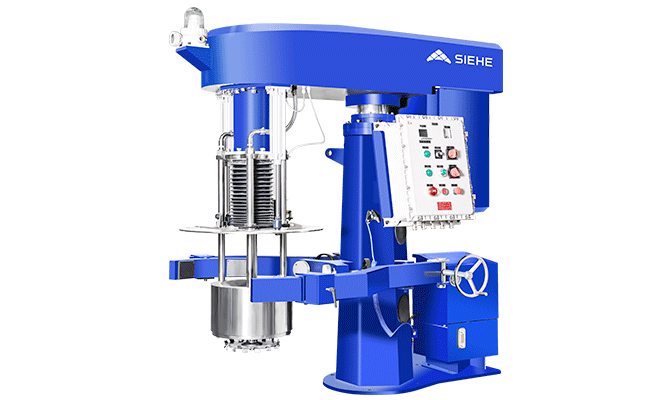

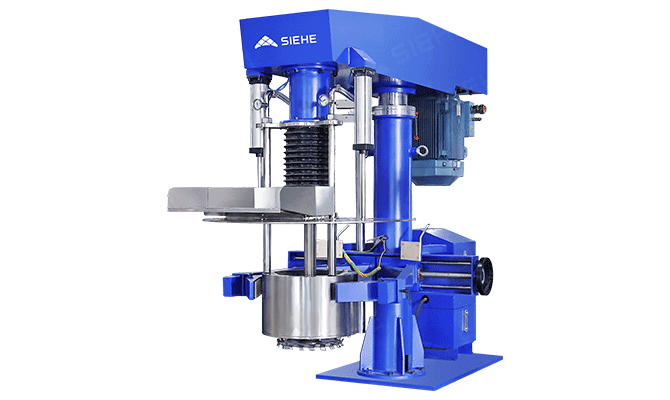

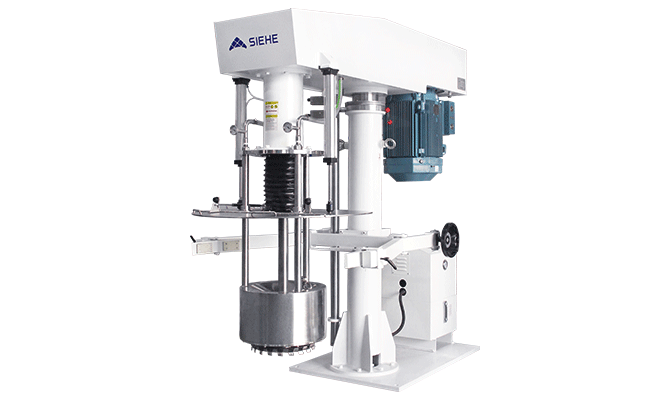

Basket Mill (Hydraulic Lifting)

Basket Mill (Hydraulic Lifting) integrates dispersing and grinding into one machine, suitable for grinding liquid materials with mid and low viscosity. It is a batch type industrial production machine with suitable and reasonable basket structure, easy to clean and to change colors / varieties. Lifting structure adopts integrated hydraulic tank as actuator, stable lifting, environmental and without leakage. It is an ideal grinding machine for materials with many varieties and many colors.

نظرة عامة على المنتج

| Materials Viscosity |

≤5,000 cps

|

| Production Capacity |

50-2,000L

|

| Application Industry | Suitable for dispersing, grinding materials in industries such as biology, pharmacy, cosmetic, food, paint, ink, color paste, dyestuff, fertilizer etc.. (For more application industry, please click “Free Consultation” |

| Application Materials | Materials shall be with viscosity less than 5000cps, with comparatively high requirements of final grinding result or with many varieties such as emulsion paint, industrial paint, color paste, water-borne ink, fertilizer suspension, enamel etc. |

مزايا المنتج

-

High grinding efficiency and excellent grinding result

Driven by the strong kinetic energy, the zirconium pins drive the grinding medium inside the basket to carry out irregular movement. The mediums crush, friction with each other to grind the powder into smaller particle size within a short period. For general materials, it can be down to approx. 5um, some even can be down to submicron or even nano level.

-

Convenient and safe operation

Adopt hydraulic tank as lifting actuator. Control the hydraulic up, stop, down through the oil pump, easy operation and stable.

With different clamping types to fix the tanks properly to prevent from accident due to the tank displacement during operation. -

Little temperature increase, stable finished product

The tank working with the machine is with cooling jacket. Excellent cooling result can be achieved by inputting cooling water into the jacket when the machine is running . Normally the temperature increase will be less than 10º. Basket part with jacket can be customized.

-

Customized options

The machine can be Exproof type.

Grinding chamber can be made of Zirconium.

The machine can be vacuum type.

The materials for the machine can be SS316L.

المعايير الفنية

| Model | Power

(kw) |

Speed

(rpm) |

Basket

(L) |

Bead size

(mm) |

Capacity

(L) |

Lifting

|

| SYM-11 | 11 | 0-1450 | 7.9 | 0.8-2.4 | 70-160 | Hydraulic lifting |

| SYM-15 | 15 | 0-1450 | 11.6 | 0.8-2.4 | 100-250 | |

| SYM-18.5 | 18.5 | 0-1200 | 17.6 | 0.8-2.4 | 130-320 | |

| SYM-22 | 22 | 0-1200 | 21.7 | 0.8-2.4 | 160-400 | |

| SYM-37 | 37 | 0-1000 | 33.4 | 0.8-2.4 | 300-650 | |

| SYM-45 | 45 | 0-1000 | 48 | 0.8-2.4 | 400-800 | |

| SYM-55 | 55 | 0-800 | 59.5 | 0.8-2.4 | 500-1200 | |

| SYM-75 | 75 | 0-700 | 75 | 0.8-2.4 | 700-1600 |

Remark:

Special working condition such as high temperature, high pressure, explosive, combustble and corosive etc. detas are required for correct model selecionIf any change in the above table, subject shall prevail without notice.

The table cannot include all products, please contact with our sales engineers for more information.

معلومات الاتصال

-

المكتب

عرض الخريطة

ص. 305-307، المبنى 1، رقم 168 طريق تايهونغ,

منطقة هونغكياو التجارية، شنغهاي الصين

-

المصنع

عرض الخريطة

بلوك D2، D5 Intelligent Industry Park, No. 2777 WanfengRd,

منطقة جينشان، شنغهاي، الصين

-

Tel

+86 21 52913185 / 52913186

-

Fax

+86 21 52912822

-

Email

اترك لنا رسالة

يُرجى التكرم بملء النموذج التالي إذا كان لديك أي سؤال أو لمزيد من المعلومات، وسوف نقوم بالرد عليك في أقرب وقت ممكن.